High Control Accuracy in Aseptic Applications

Automated turnkey solution for installation in tight spaces

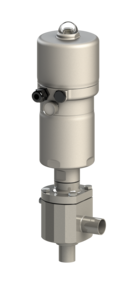

Type 3349/3379, the compact automated unit with optional positioner for use in aseptic applications, was introduced at the Drinktec trade show in 2013. Since then, it has been used in the pharmaceutical and food industries, mainly in applications where the highest control accuracy is expected.

The Type 3349 Valve is made of low-ferrite stainless steel, has a cavity-free body and can be supplied with different aseptic connections, such as welding ends, threaded ends, flanges, clamps. The valve is suitable for CIP (cleaning-in-place) or SIP (sterilization-in-place). All wetted materials are approved according to FDA, USP Class VI-121 °C and EC Regulation 1935/2004. The diaphragm seal mounted on the plug stem guide reliably prevents contamination of the process. A test connection allows the diaphragm to be monitored for leakage.

Combined with the stainless steel Type 3379 Actuator, the valve forms a compact unit suitable for installation in tight spaces. Internal air routing prevents the ingress of dirt or water.

To achieve a high control accuracy, the Type 3724 Positioner can be integrated into the actuator: operation of the positioner on site is easy and intuitive thanks to just three keys and the display.