Ventilation systems are used in offices and industrial buildings to create a healthy indoor climate. These systems include air filters, which stop contaminants from entering both the ventilated spaces and the ventilation systems themselves. According to the VDI 6022 regulations, air filter inserts must be replaced – at the latest – when their permissible final differential pressure has been reached or when technical and/or hygiene-related malfunctions occur. A measured variable, in this case the differential pressure, is used to assess the condition of the filters. If the differential pressure gradually approaches the permissible final value specified by the filter manufacturer, this is an indication that the filter will have to be replaced soon. If the differential pressure drops significantly, the filter is damaged and needs to be replaced immediately.

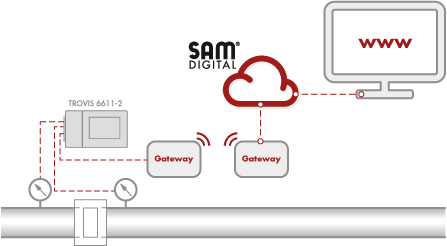

SAM DIGITAL, SAMSON's platform for digital solutions, makes it possible to continuously monitor the differential pressures measured at the filters. The test setup is based on the wireless transmission of the measured values to the SAMSON cloud. An easy-to-grasp diagram plots the differential pressures measured at different filters over time. Filters that need to be replaced are shown in a list and their location is indicated on a geographic map. On top, operators can be kept up to date on the filters' condition by e-mail, text message and/or voice-mail notifications.