Replacing Old Valves With Valve Engineering Expertise

Improved valve performance thanks to SAMSON on-site support

In many countries, chemical and petrochemical plants still run with old equipment, including valves. The manufacturers of some of this equipment have long since gone out of business, which makes it impossible to get spare parts.

As safe operation is one of the key requirements placed on the often highly complex plants, there is no other way than to replace the old valves. Operators expect the new equipment to control with greater accuracy, achieve a better cost-effectiveness and ensure safe plant operation. It takes in-depth expertise to meet these requirements and seasoned specialists who can assess the process on site.

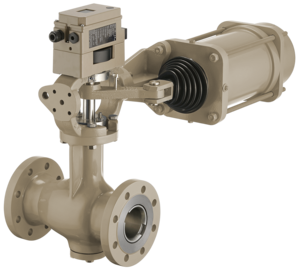

This is exactly what the product experts working at SAMSON and the SAMSON subsidiaries do all across the world. In many cases, a double-seated valve can be replaced. These old valves neither possess the required SIL 2 rating, nor do they comply with the TA Luft fugitive emissions standard. Plant operators are very satisfied with the support they are getting and keep discovering new opportunities to improve their plants.