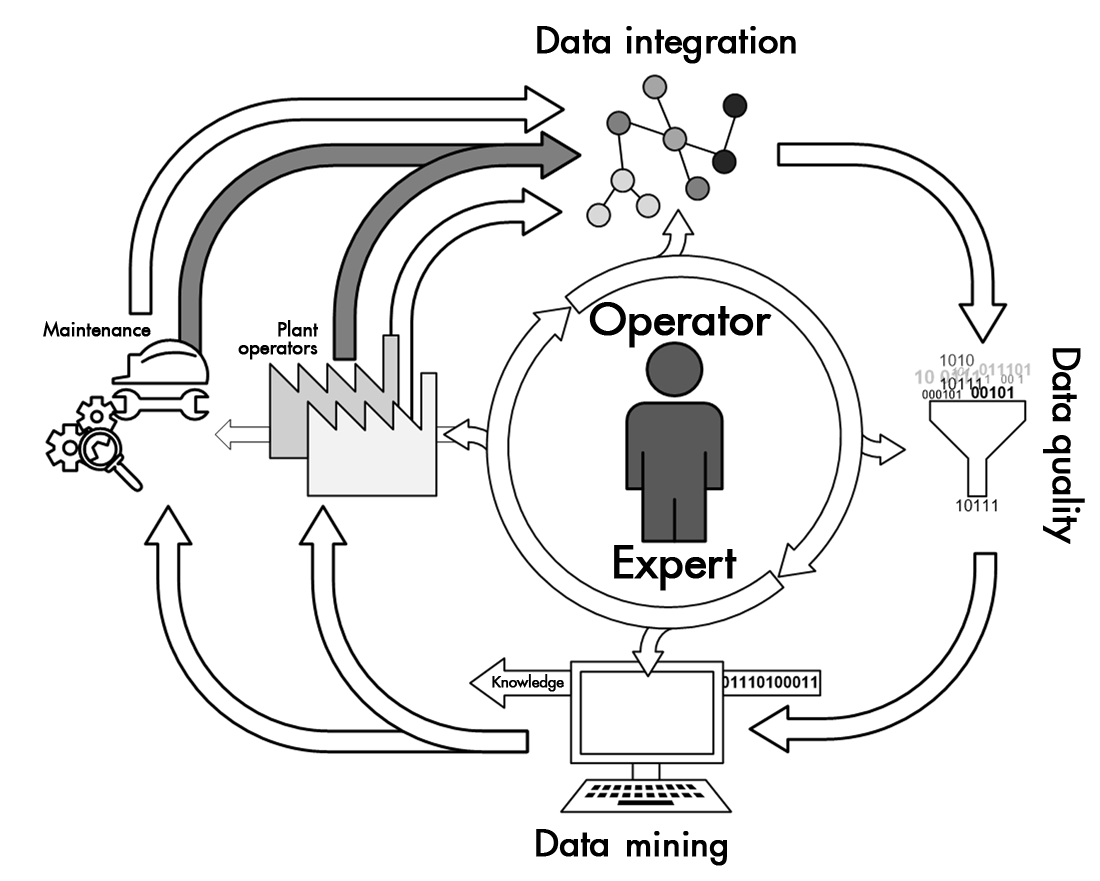

The process industry plays a leading role in Germany's high-tech industry landscape. Pharmaceuticals and specialty chemicals are produced for the worldwide markets in plants with a high degree of automation. Unscheduled plant downtimes caused by the failure of technical installations result in delayed delivery and high cost. The wide variety of different processes, production spread across several sites as well as the large number of companies involved and IT systems used have made it difficult to thoroughly analyze the data available to plant operators, service providers and equipment manufacturers and derive a benefit for all companies involved from these analyses.

This is where the SIDAP research project ties in. The goal is to develop an approach for the aggregation, analysis and preparation of data across companies and production sites to achieve a better data quality and considerably expand the data base. This will make it easier to learn from different data sources and integrate ideas from other fields, such as data-mining algorithms, data and system architectures and cloud-computing technologies. At the same time, the plant operators' interest in protecting their process know-how is respected. In the SIDAP project, all this is done in close cooperation between the process industry leaders, IT and MES companies as well as researchers dealing with integrated information systems for process automation and operational applications.

Based on the usage data compiled in the operators' production plants, device manufacturers can analyze device malfunctions and implement predictive maintenance systems. Plant operators benefit from being able to make better use of the installed equipment and thus optimize plant availability.