SAMSON VETEC

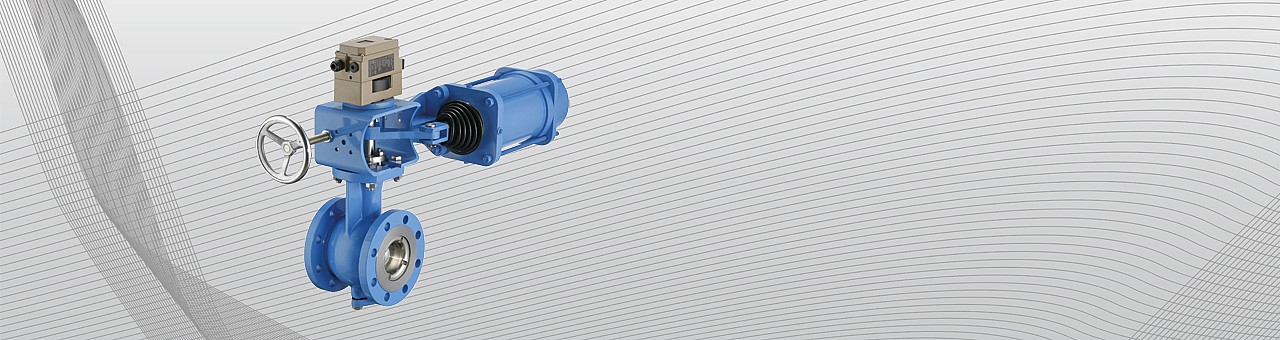

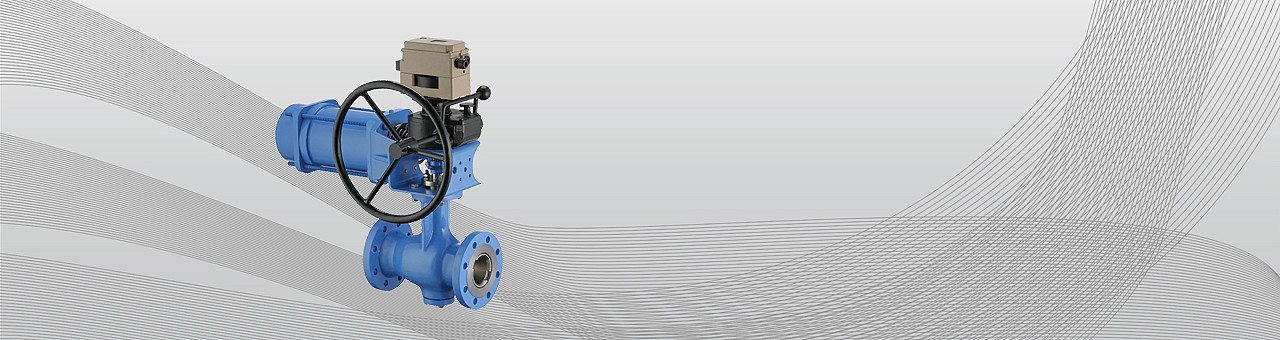

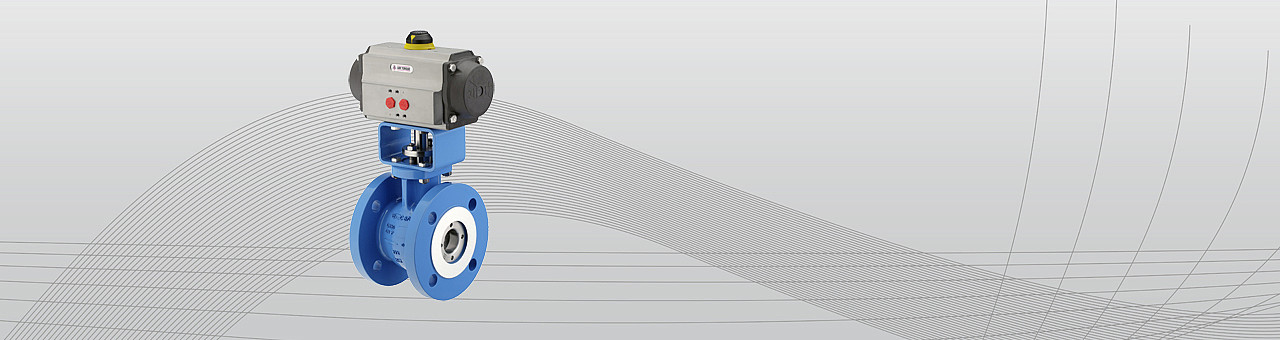

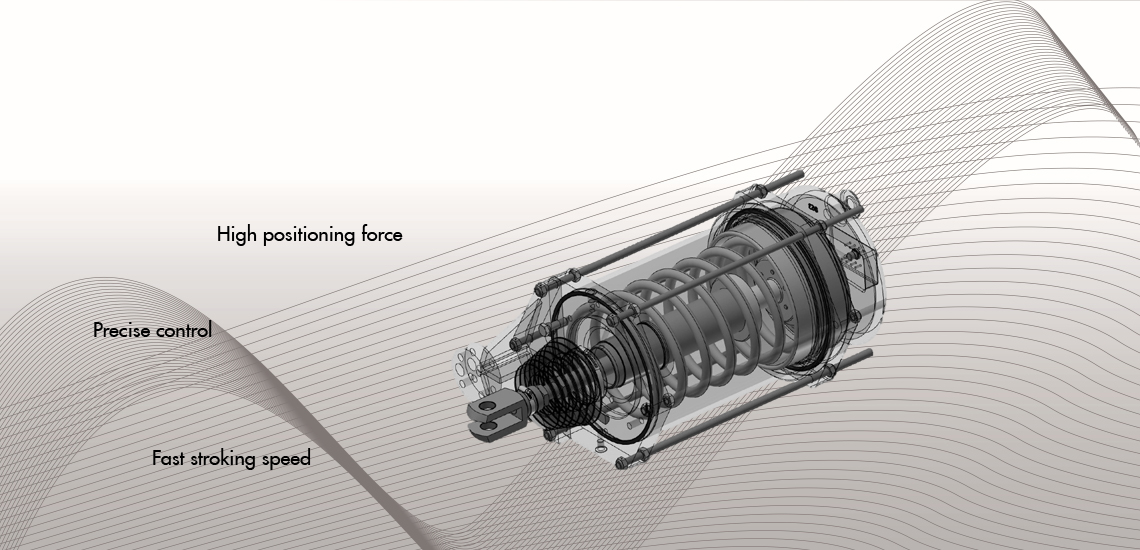

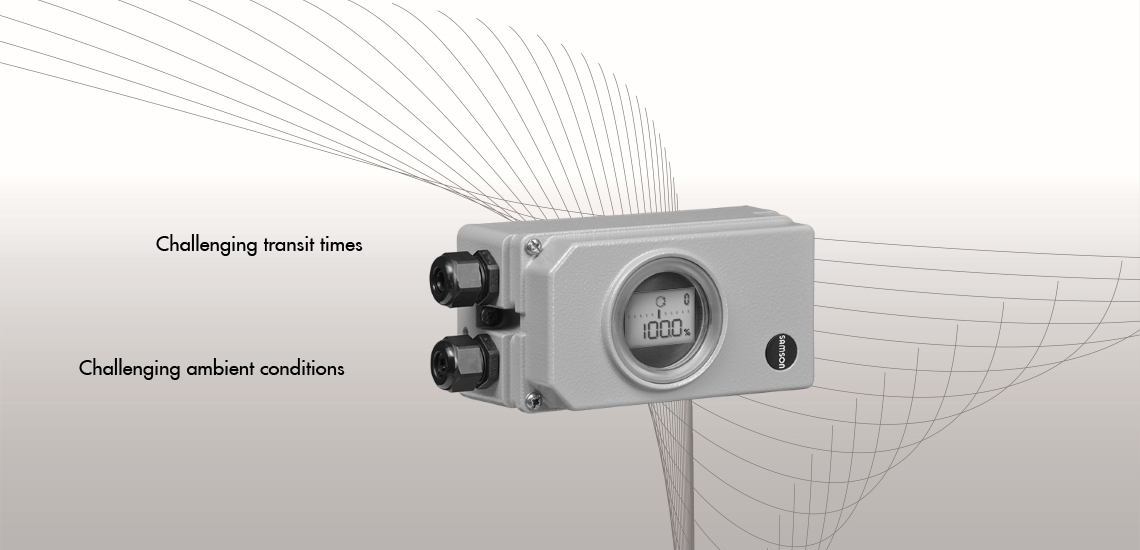

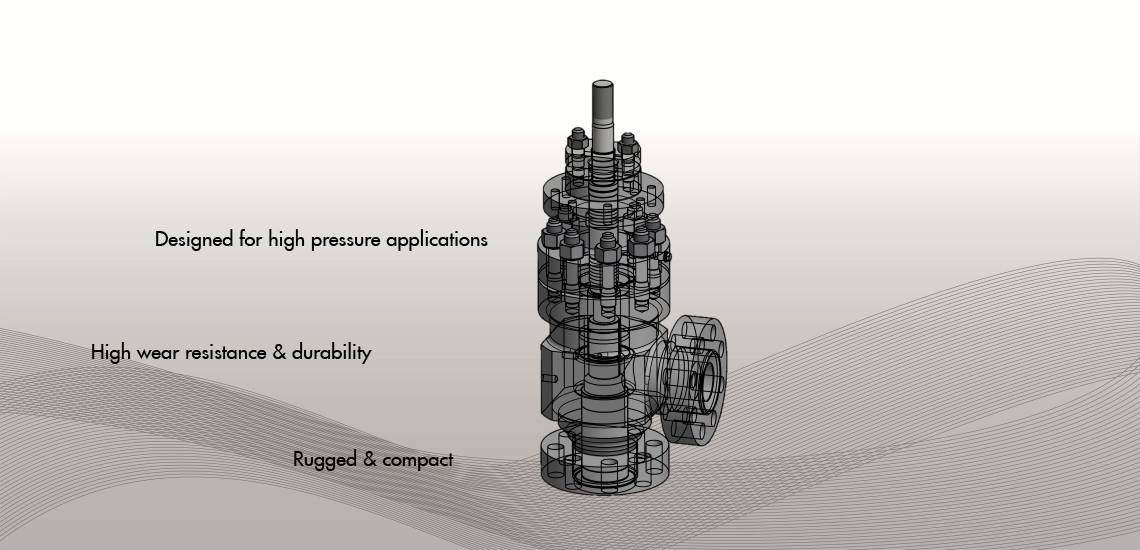

Rotary plug valves, high-pressure angle valves and pneumatic actuators

VETEC's strength is the daily handling of the specific requirements of our customers. Each application is given its own solution by us. The durability of our products through robust construction and the quality standard at the highest level are terms that have always been associated with the name VETEC.

Products

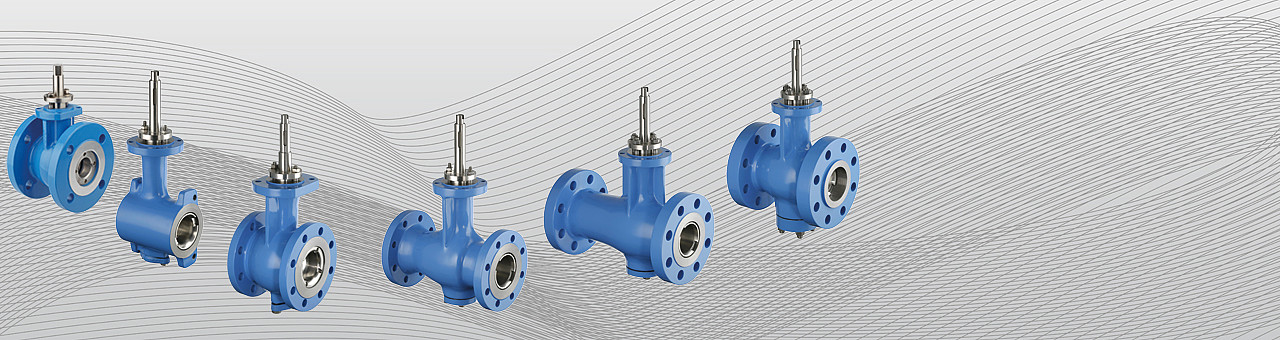

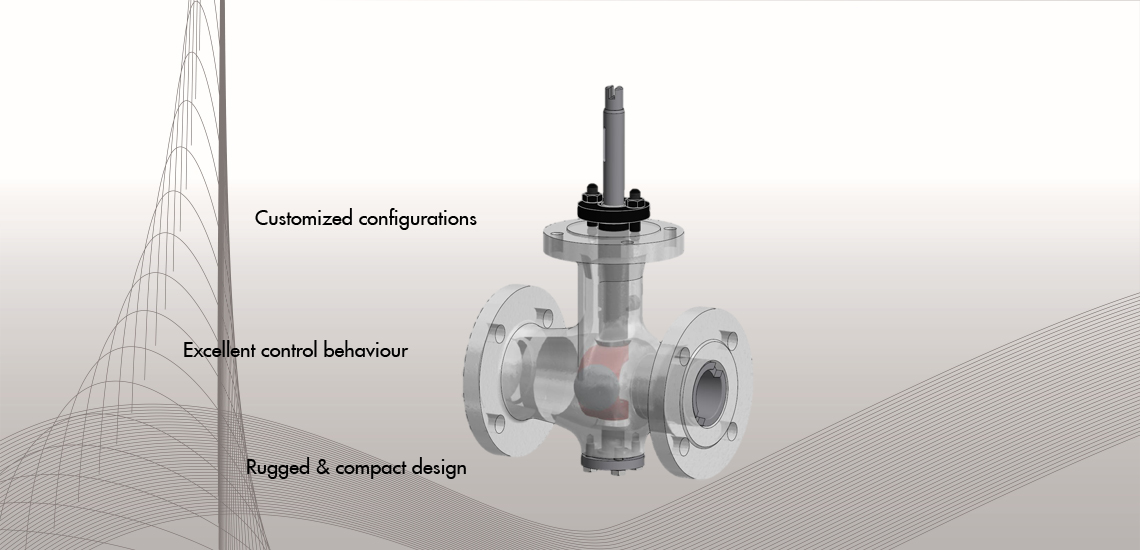

VETEC's core product is the rotary plug valve, a success story with an increasingly broad range of applications. Its modular design and the variety of variants make the VETEC rotary plug valve universal and suitable for all applications. In addition to standards for cast steel and cast stainless steel grades, we offer steels and stainless steels for low and high temperature applications as well as special materials, such as nickel-based alloys, duplex and superduplex, Monel®, titanium, zirconium and bronze alloys for oxygen or seawater.